Tube Sealing Machine

- Key Features:

- -This machine is suitable for co-extruded plastic tubes & for Lami tubes.

- -Can seal a tube with 50 mm diameter.

- -Uniform & leak proof welding joint.

- -High Efficiency Ultrasonic Sonicator.

- -Semi automatic operation.

- -Inbuilt trimming attachment.

- -Rigid frame construction.

- -Pneumatic speed regulator for sealing head & trimming head.

- -Manual tuning with reading of "idling" "welding power" on the instrument.

- -Ultrasonic test.

- -Automatic controller.

- -Triple time for delay time, welding time & holding time.

- -Welding pressure adjustable up to 6 bar.

- -Automatic controller.

- -Microprocessor based controller.

- -Weld time, Hold time settable in the steps of 100 milliseconds.

- -Microprocessor based controller.

- -Digital counter up to 100,000 counts–resettable.

- -Digital Bar graph to indicate tuning & energy during the welding cycle.

- -Microprocessor based controller.

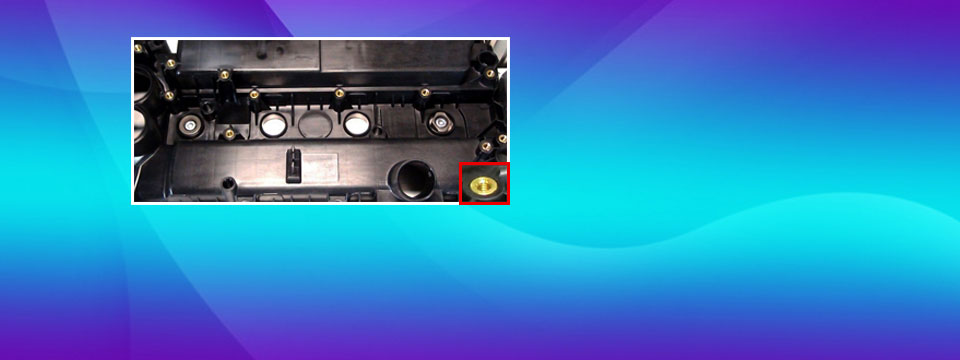

- -Leveling screws provided on the ultrasonic assembly for easy settings & alignment of horn & anvil.

Specifications of 1.2 Kw/20 KHz. Ultrasonic Tube Sealing Machine

- Electrical Input

- Voltage: 230 +/- 5 V AC single Phase.

- Current: 8 Amps.

- Max. Power: 1.5 Kw. .

- Output

- Frequency: 20 kHz.

- Power: 1 200 watts.

- Operating Frequency: 20 KHz.

- Generator Dimensions: 580*430*150.

- Feather Touch screen for parameter settings on the front panel.

- Two line LCD display for parameter reading & setting.

- Generator weight: 17 kg.

- Co-axial Cable length: 3 meters.

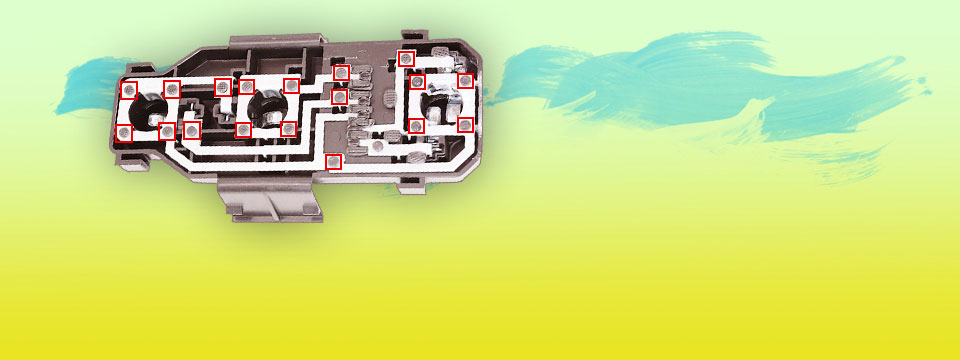

- Sealing & trimming Head.

- Mounted in Housing made up of 10 mm MS plates with Powder coating/plating.

- Rigid MS columns for support .

- Two pneumatic cylinders which operate sequentially.

- Movable Sealing Horn & anvil.

- Machine Operation and Productivity

- Auto cycle with Pneumatic System.

- Productivity : 12 to 15 Pcs per Minute.