Products

Ultrasonic Plastic Welding Machines

Spin Welding Machine

Applications

Most suitable for nylon 6,66 derlin, PP and other thermoplastic circular parts.

Key Features

-

PLC controlled high speed servo motor

Precise speed and Position control.

Adjustable Speed , Pressure, Spin Time, Hold Time

Leak proof welding

Compact and rigid frame design

Ultrasonic Plastic Welding Machine

Types

Ultraweld 1200 watt / 20 KHZ

Ultraweld 2000 watt / 20KHZ

Ultraweld 2600 watt / 15 KHZ

Ultraweld 4200 watt / 15 KHZ

Ultra Weld Spot Welding Machine 1200 watt/ 20 KHZ

Key Features

-

High Efficiency converter

Rigid frame construction

Pneumatic speed regulator

Frequency tuning with reading of idling & welding power on the instrument

Triple time for delay time, welding time & holding time

Ultrasonic Cleaning Machines (Single Chamber)

Types

Ultrasonic Cleaner 250 Watt Size: 400mm x300mm x150mm: 18 lit

Ultrasonic Cleaner 500 Watt Size: 500mm x400mm x200mm: 40 lit

Ultrasonic Cleaner 750 Watt Size: 675mm x475mm x200mm: 63lit

Ultrasonic Cleaner 1000Watt Size: 600mm x400mm x300mm: 75 litre

Heat Staking Machine

Applications

PPLC controlled with HMI.

PID Temperature controller to maintain the correct temperature of the heating elements

Power supply: 230 VAC, 50 Hz, Single phase @ 1.5 Amp.

Pneumatically operated machine.

Air supply: Dry & clean air @ 6 bar pressure.

Key Features

-

Air consumption: 3 to 5 CFM

Consumables: heaters, Heating elements.

Sturdy MS frame with powder coating.

Pneumatic / Hydraulic cylinder for heating element movement.

Productivity: 2 to 4 pieces per minute.

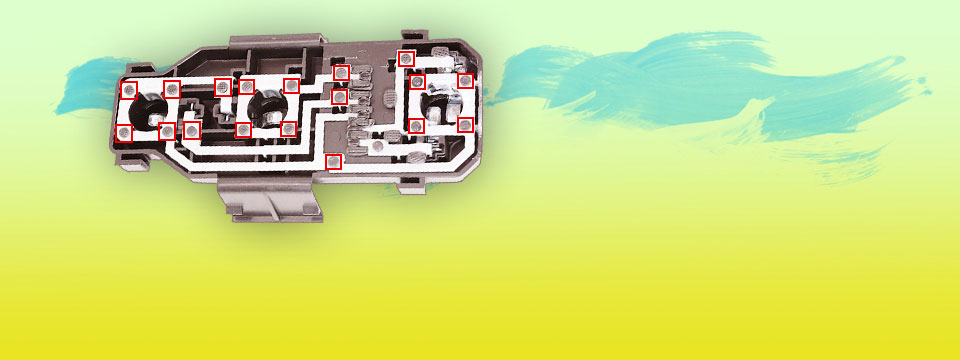

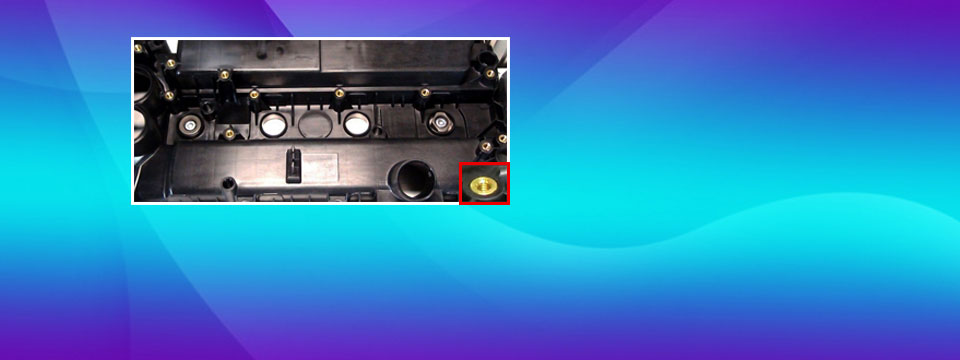

Heat Insertion Machine

Key Features

Heat insertion is the process which finds applications in joining plastic parts. Thermoplastic parts as such are too soft to sufficiently hold threads and offer tight joints. To overcome this problem threaded inserts of brass or steel are added post molding.

Heat Insertion is a process wherein a heated thermal tip embeds a metal insert into a plastic application.

Used for assembly of metal parts with plastic parts permanent.

Such parts used in automotive for fasting with metal parts in Vehicles.

Air supply: Dry & clean air @ 6 bar pressure.

Specialize in Apllication

-

Foot Board – Bolt inserts

Intake manifolds – Nut Inserts

Washer Tanks – Bushes

Radiator Tank – Bushes

Tube Sealing Machine

Applications

Auto cycle with Pneumatic System.

Productivity : 12 to 15 Pcs per Minute.

Key Features

-

This machine is suitable for co-extruded plastic tubes & for Lami tubes.

Can seal a tube with 50 mm diameter.

Uniform & leak proof welding joint.

Ultrasonic test.

Automatic controller.

Ultrasonic Homogenizer / Probe Sonicator

Key Features

Low transducer losses permit maximum cleaning action.

Modular generator for easier modification / Servicing.

Rugged and easy to clean stainless steel Probe.

Frequency 20 KHz.

Wattage: 1000 watt.

Sample Capacity : 1000ml-7000ml.

One Year Warranty.