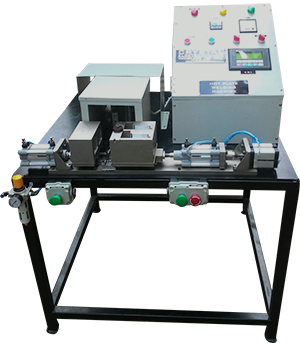

Hot Plate Welding Machine

- Key Features:

- - PLC HMI Controlled Machine

- - Safety Screen provided for operator Safety

- - PID Temperature controller to maintain the correct temperature of the heating elements

- - Pneumatically operated machine with Festo make Cylinder

- - Replaceable Teflon sheets will be provided on top & bottom of the heater block to avoid sticking of the component to the heater

- - Teflon Coating Hot Plates.

- - Sturdy MS frame with powder coating.

- - The cycle starts by pressing the 2 hand push buttons.

- - Logic controls will be through PLC ( Fuji Electric Make).

- - MCB will be provided for input supply.

- - Acrylic sheet framework will provide for machine.

- - Temperature Interlock and All possible Interlock will be provided to Machine.

Specifications for Hot Plate Welding Machine

- Electrical Input Voltage: 230VAC ± 2V Single Phase

- Pneumatic: Air Supply: 4 to 6 CFM @ 3bar pressure

- Timer and relay logic control operation

- Leak proof joining All machined parts in general will be Blackened/Nickel plated

- Fabricated parts will be powder coated as per your color scheme

- Relays will be provided for all output from PLC.

- All actuators & indicating lamp will be of TECHNIC / IDEC make